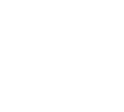

All your data - In ONE view

- Monitoring

- Analysis & reporting

- Reliable real-time data

- Alarms and notifications

- Control at all levels

17

years of experience

+13,000

assets connected worldwide

compatible with solar PV, wind,

and hydro plants.

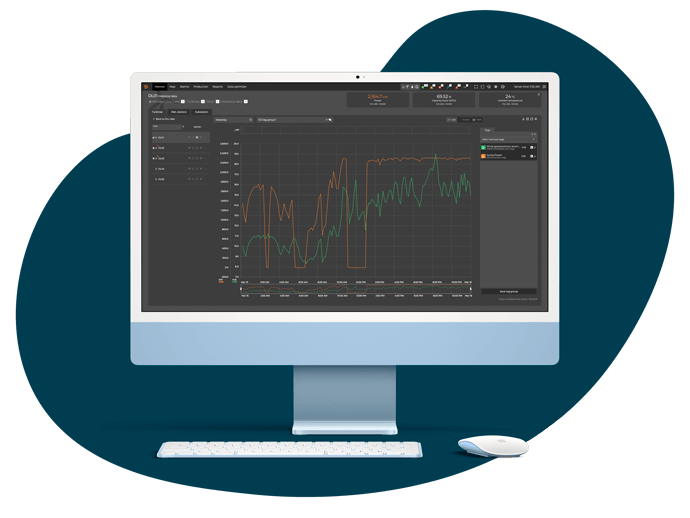

What is the best solution for you?

Our flexible systems fit every setup, whether you want to replace your existing SCADA software on-site

or seamlessly add new parks across your fleet for a complete overview at your control room data center.

Gather all your data, assets, and power plants in one unified system

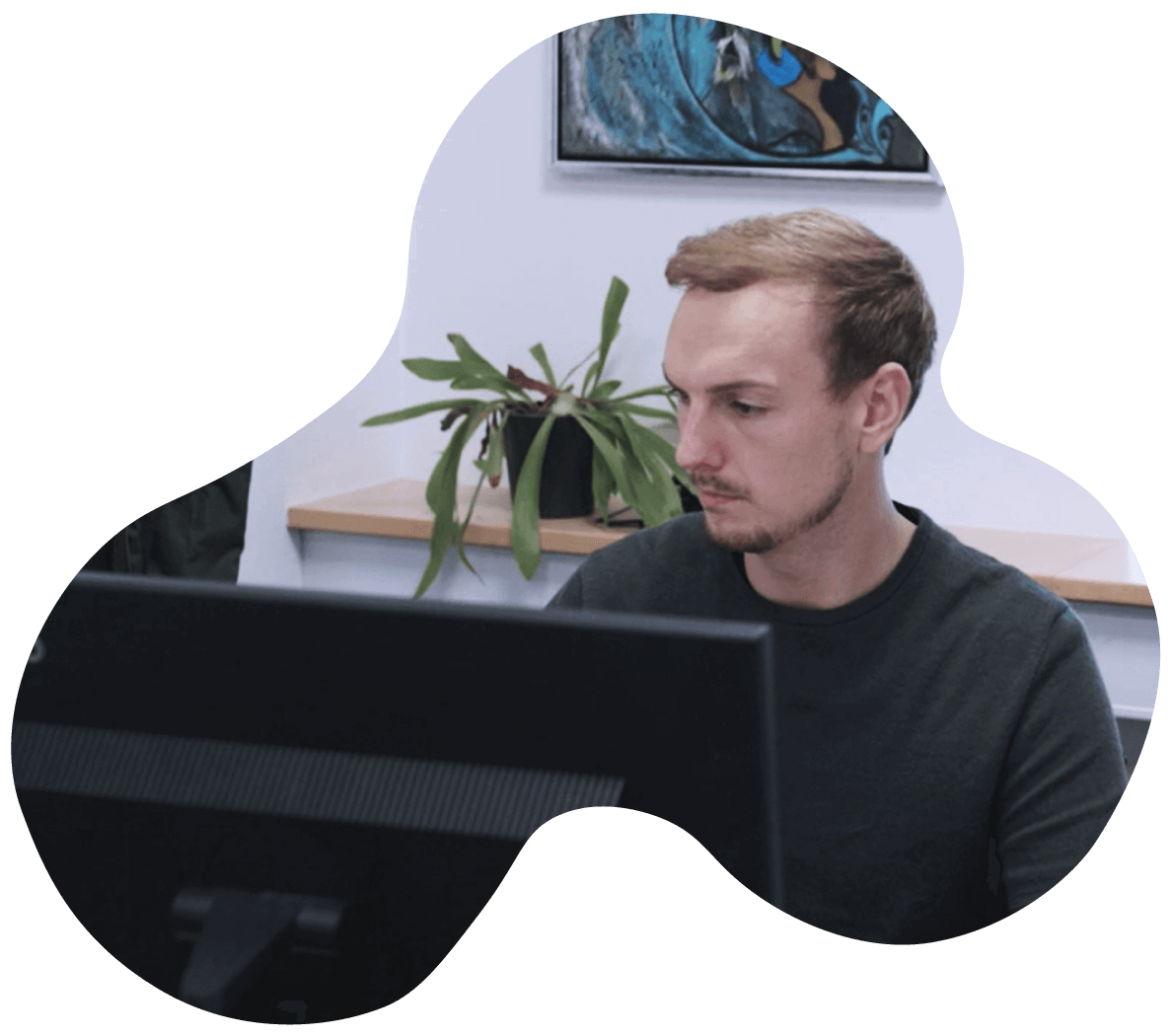

Monitor your assets in one screen

Regardless of manufacturer, you can monitor, analyze, and control your assets through one system with one login

- Unify all your renewable plants in one view

- Monitor and control your parks remotely

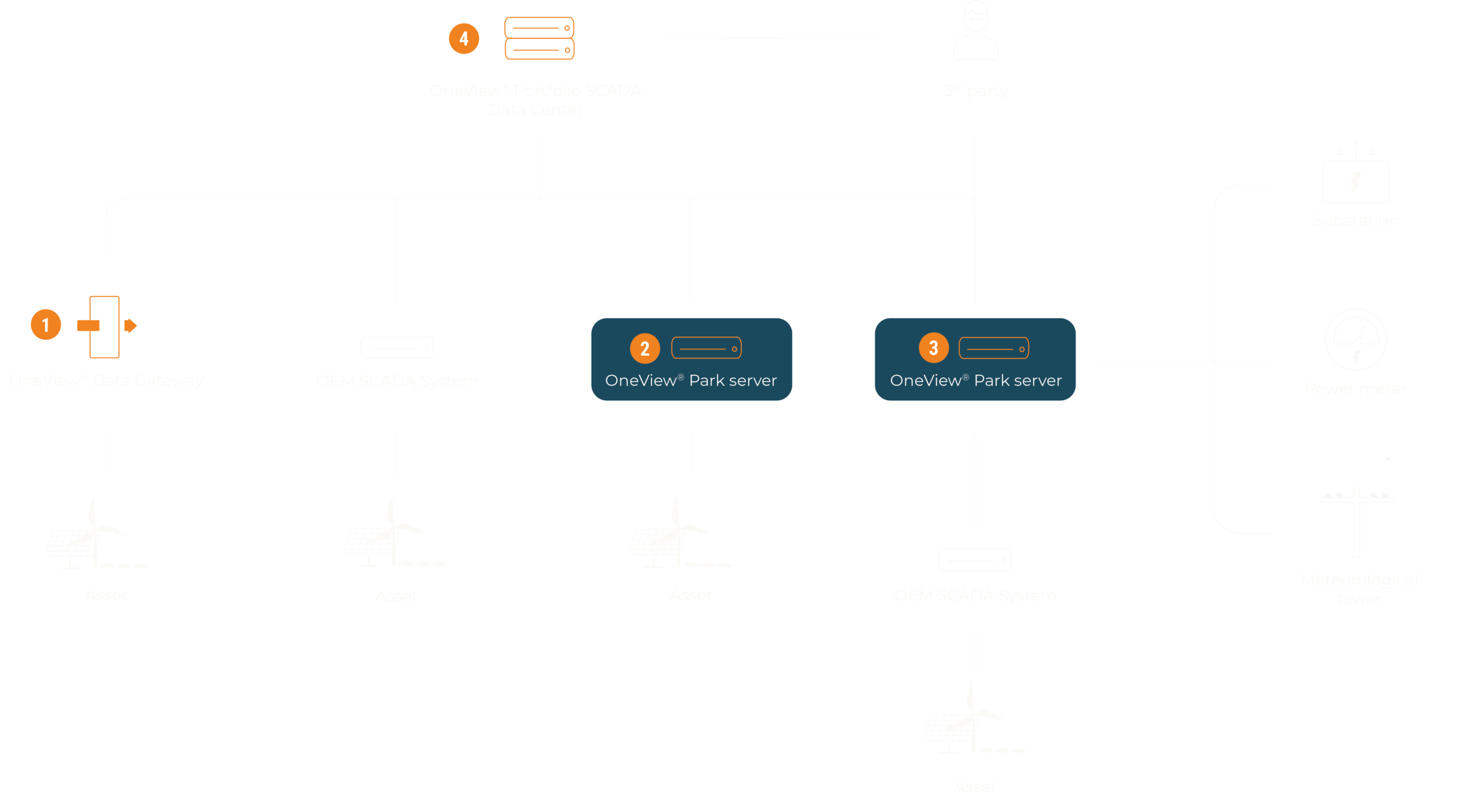

- Analyze your production and production loss

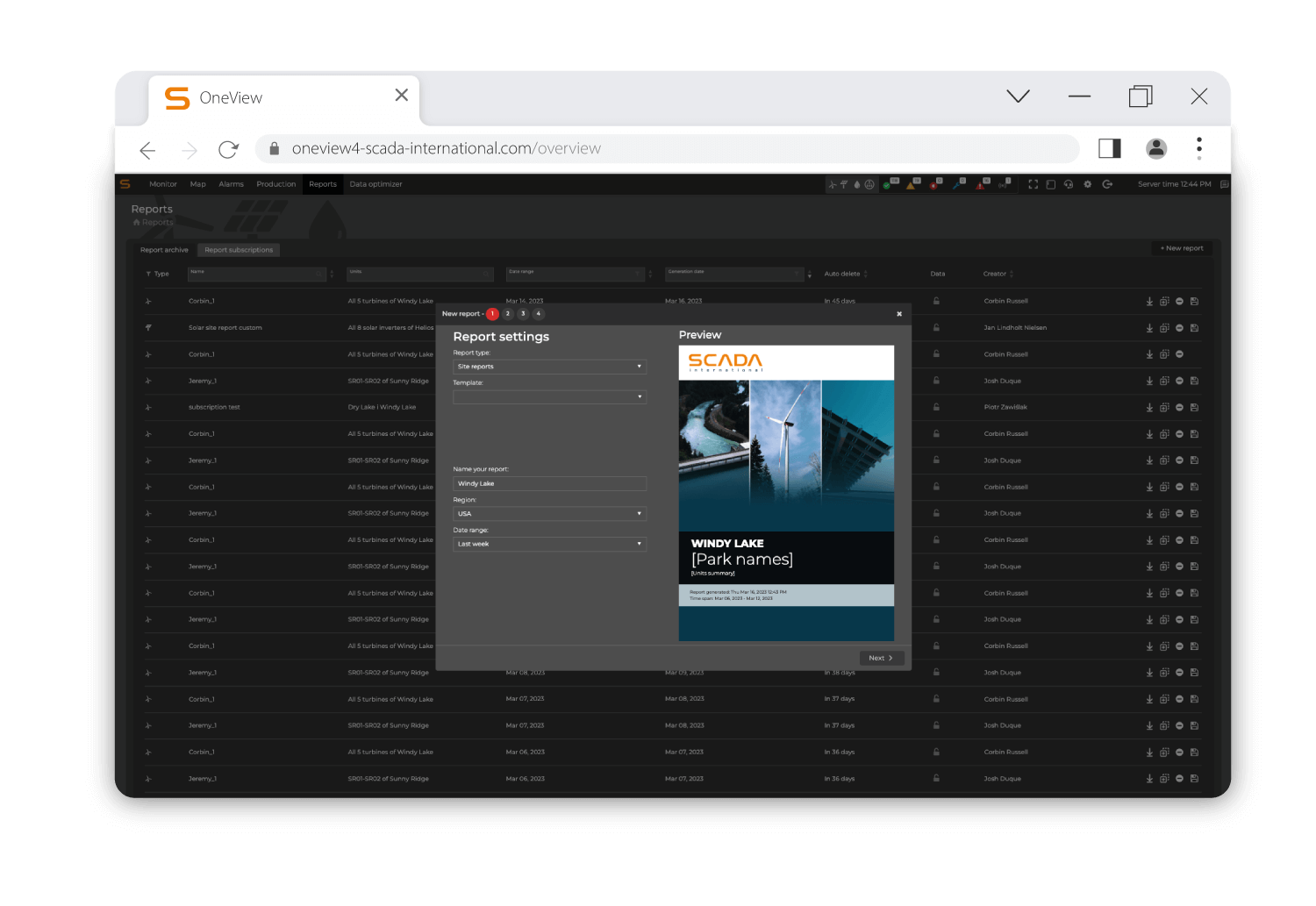

Generate automatic and customized reports

The system includes an advanced reporting engine that enables you to quickly and effortlessly generate reports

- Customized reports to analyze the performance

- Schedule reports and add subscribers

- Get third-party access for control and reporting

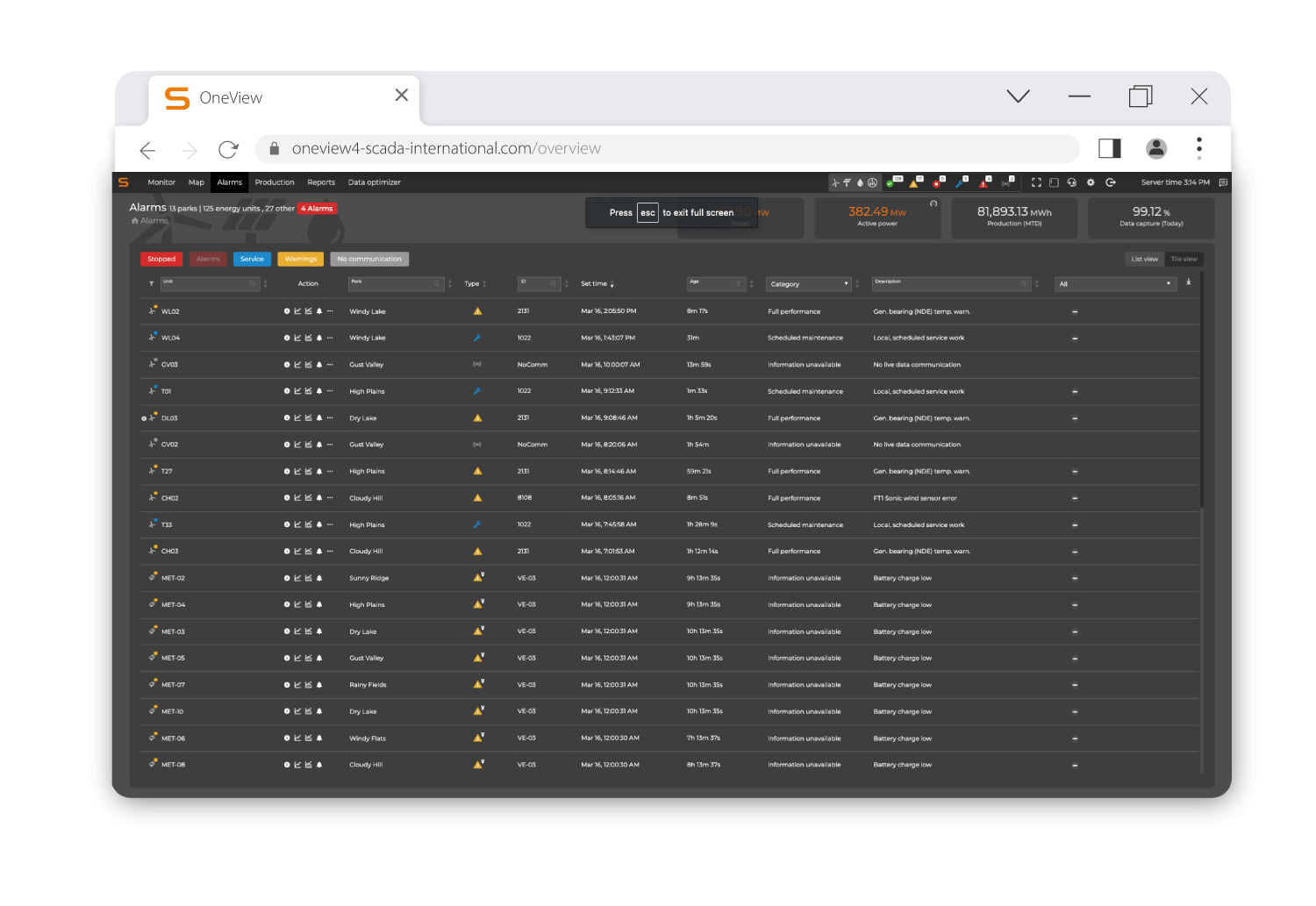

Mitigate performance issues and reduce downtime

Use the system to react quickly to alarms and events to ensure optimized plant operations and performance

- Receive notifications on alarms and events

- React to warnings to prevent system failures

- Keep track of alarms to optimize operations

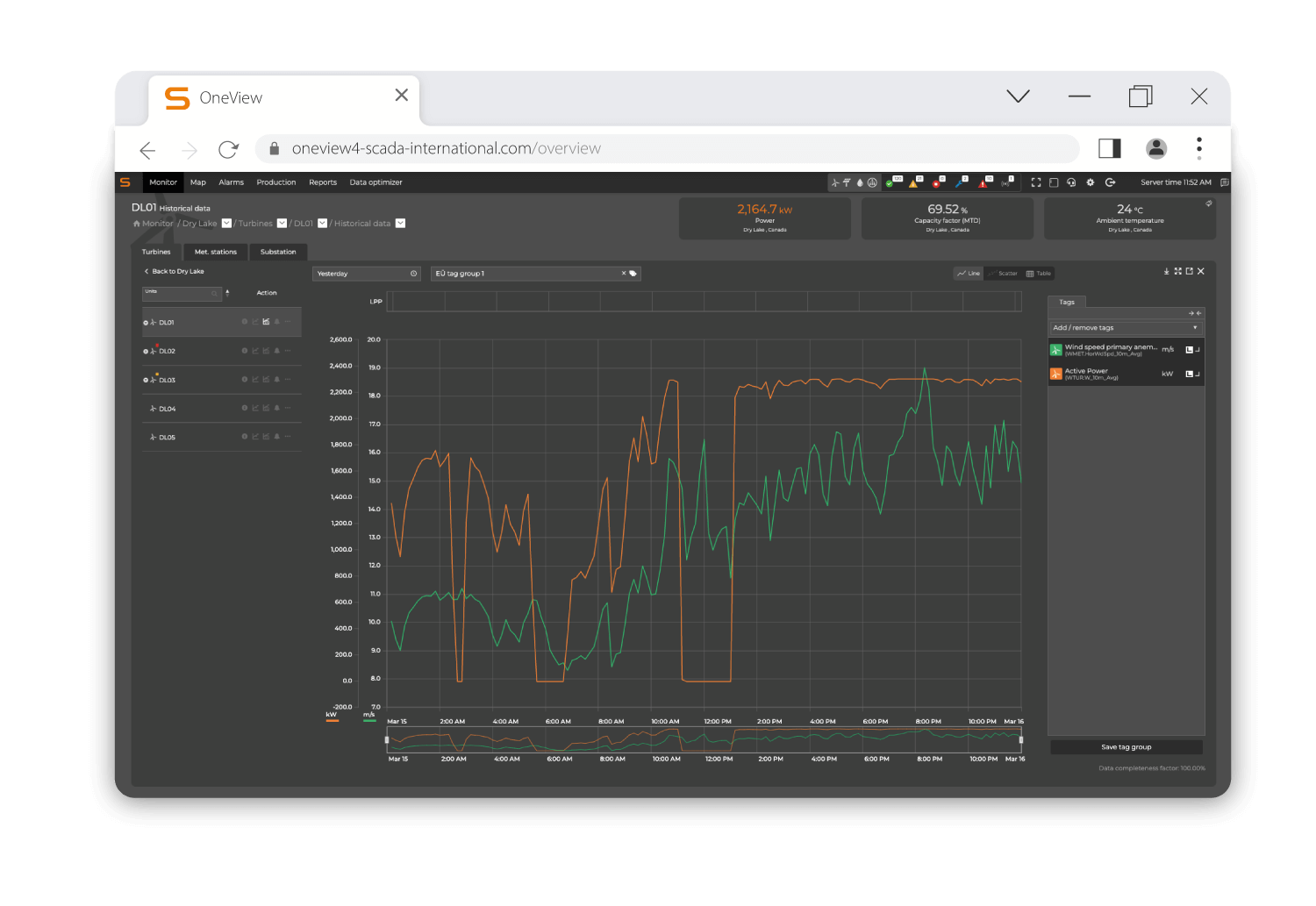

Access mission-critical live and historical SCADA data

Connect to all plant devices and parks in your portfolio for complete control and ownership of data and systems

- Real-time and historical collection of asset data

- Simplify the operations with normalized data

- Access availability and performance data

Accurate data for reliable reporting

Discover Robotic Data Intelligence

Reliable data enables you to increase availability and ensure your system runs optimally. Unfortunately, in data science, it is common that 80% of the time is spent on cleaning and getting the data ready for analysis rather than actual analysis, giving you fewer resources for business-related analysis and optimization.

Our patented automated data enrichment feature in OneView® SCADA, the Robotic Data Intelligence, allows you to clean, normalize, and correct data automatically. It acquires raw data from the power plants and uses smart algorithms to create virtual events to cover missing events automatically. The cleaned and corrected data can then be presented in customized reports for performance and production overviews.

- Update lost periods automatically with algorithms

- Estimate production at lost periods automatically

- Revise the lost or incorrect periods manually

A solution tailormade for you

24/7/365 access to service and SCADA support

Configuration on own hardware or hosted solution

pricing

modules

user-friendly

interface

and support

training

Use smart tools to optimize your business

SCADA International offers several features in our OneView® SCADA system that enables you to improve and analyze your processes and production, thus adding value to your business performance. With our expertise and market insight, we know the challenges you are facing and how our solutions can fit your needs.

Diagnostics

Avoid downtime with the automatization of manual routines

Being able to analyze historical data and spot renewable energy assets that do not perform well has typically been the job of the very skilled technicians.

However, with large and growing portfolios, using manpower for detecting and analyzing events is no longer feasible. Computer systems are much better and faster to detect deviations and outliers.

We offer an automated diagnostics feature and learn the technicians’ know-how to use it to create automatic system support routines which reduce the need for specialized manpower resources.

Lost Production Advanced

Get an efficient tool for documentation, claims, or compensation

Lost production is an important factor to be aware of when dealing with asset management – whether you want to learn more about compensation or identify areas of operation that can be optimized.

We offer an automated, detailed, and continuous Lost Production calculation. We perform a setup of rules to automatically identify and prioritize overlapping lost production periods.

Use the tool for advanced reporting, easy benchmarking, and fast identification of sources of lost production.

Why customers choose us

- We have vast experience in SCADA across the full value chain

- We are experts in data normalization, and our system is compatible with a wide range of manufacturers

- Our solutions fit every setup and can communicate with many different devices and systems

- Our solutions enable third-party access to, e.g., power traders and balance responsible parties

- We are an independent provider focusing on your needs

- We are with you in every phase of the project

- We enable reduced data and system complexity