Circularity. A word that has recently gained much attention in the renewable energy sector. With the prospect of a renewable future – and thus a more sustainable future – more and more people have started discussing what happens in the afterlife of renewable assets and their materials.

Perhaps you have heard about discarded wind turbine blades ending up in landfills due to the challenges of recycling the non-biodegradable blades that are made of resin-coated fiberglass, which is difficult to separate and recycle.

And perhaps you have seen pictures of turbine blades reused as bike shelters, exploring “the blades’ potential reuse in architectural and engineering structures.”

And one of the industry’s most prominent OEMs recently announced a new circularity solution to also put a stop to the landfill of turbine parts. That more companies will follow this trend in the following years is not unlikely.

But what are the possibilities when looking at the SCADA systems of renewable assets? How can these be recycled or repurposed? And is it even worthwhile doing so?

In this blog post, we discuss how you can extend the lifespan of both your SCADA systems and renewable assets.

The lifetime of renewable assets vs. SCADA systems

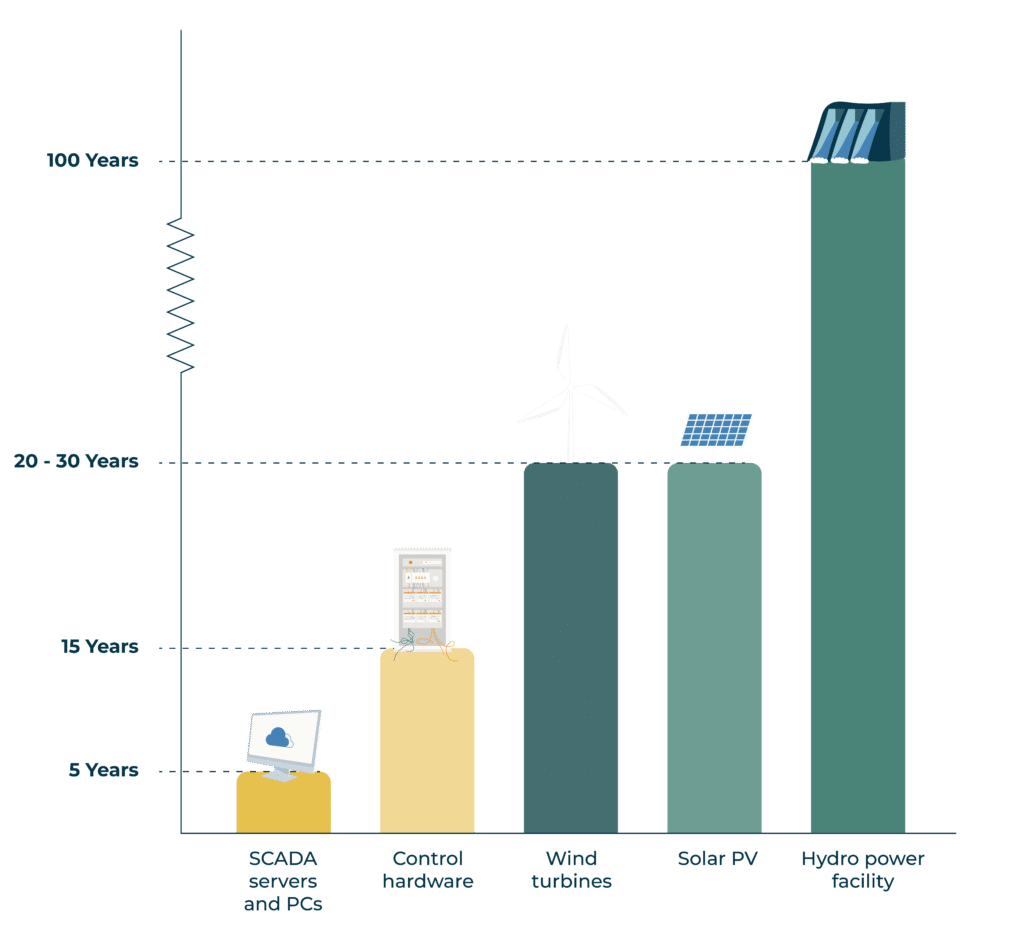

The typical life span of a wind turbine is 20-30 years, meaning many of the turbines you see in the landscape today might have been built in the late 90s or early 2000s. As the illustration below reveals, the same goes for solar plants, whereas hydro plants can typically last for an entire century.

When installed, renewable parks have an inherent SCADA system to acquire data from the assets and enable on-site and remote monitoring, control, and analysis. SCADA systems are built-in software that quickly becomes outdated and obsolete relative to the assets’ lifetime.

Actually, SCADA systems often last only 5 years before significant updates are needed. Plant hardware usually lasts 15 years before replacements are required.

However, up-to-date software is mission-critical in operating a renewable plant today.

To put it into perspective, imagine buying a laptop 20 years ago, operating on the 2003 Microsoft Windows XP version, and still being forced to use the system to this day. The system will no doubt run slow, miss critical security features and updates, and stop you from working efficiently and improving your performance.

For renewable assets, old legacy SCADA systems and plant hardware can also result in increased downtime, gaps in communication, and an unnecessarily high level of unplanned maintenance.

Retrofitting can improve performance and efficiency

Consequently, SCADA systems are replaced multiple times during the lifetime of renewable assets. This is often called retrofitting and is a useful tool in extending the assets’ lifetime and the entire renewable fleet.

Retrofitting older wind turbines with new software and technology, contemporary control algorithms, and intelligent SCADA solutions can increase the turbine’s yearly power production, improve availability, and offer new cutting-edge applications that reduce manual work and the overall LCoE.

Another essential benefit of retrofitting is that the newly installed system most likely complies with industry requirements and standards. Being able to quickly react to performance and maintenance issues can make the plant owners more attractive to third-party business partners like power traders and investors.

Experienced and proactive service and support can get you a long way

Sometimes, plant owners are not ready to accept their faith and purchase a new SCADA solution for their plants. Replacements can be outside the budgetary expenditure and thus seen as an expensive investment. As a result, plant owners are left with outdated and perhaps unsupported SCADA systems.

However, access to an experienced and proactive service provider can assist in extending the lifetime of the assets without upgrading to a new SCADA system.

With a service agreement for your SCADA system, you not only get support when issues occur or, e.g., when wind turbines are not running optimally. Often, you will also get proactive services consisting of regular check-ups, status reports, and recommendations for system improvement.

These services provide the asset owners or site managers with essential guidance on how to improve their SCADA systems and overall performance – and, in that way, extend the lifetime of the SCADA system.

Whether extensive maintenance is sufficient or a retrofitting solution is required varies from park to park. Here, a competent SCADA service team can lead you in the right direction.